stuffed pasta automatic forming machinery

NP 500 STUFFED PASTA FORMING MACHINE (Loading on the left)

Stuffed pasta forming machine designed with three operating units:

– pasta dough rolling unit

– filling loading unit

– cutting and forming unit.

The machine’s design makes it easy to integrate, thanks to its compact size, also in an existing medium-sized production system.

All components coming into contact with the pasta and/or filling are made from stainless steel or non-toxic materials suitable for the food processing industry.

| TECHNICAL DATA | |

|---|---|

| APPLIED STANDARD | CE |

| NOISE EMISSION LEVELS | < 80 dB (A) |

| OPERATION | Electromechanical |

| OPERATORS REQUIRED | 1 |

| POWER SUPPLY | 3 x 400 Volts – 50 Hz + Terra |

| VOLTAGE VARIATION | +/- 5% |

| NEUTRAL | NO |

| AUXILIARY TENSION | 24 Volts c.c. |

| INSTALLED POWER | 4,1 kW |

| OPERATING PRESSURE | 5 ÷ 6 bar |

| COMPRESSED AIR CONS. | 80 Nl/min. |

| WATER | Not required |

| FONDAZIONI | Not required |

| LUBRICATION | Grease manual |

| TOTAL MACHINE WEIGHT | 1.550 Kg |

| CA500 CALIBRATION | |

|---|---|

| WIDTH OF PASTA SHEET | 500 mm |

| CALIBRATION ADJUSTMENT | thin sheets |

| RATE PRODUCTION | 300 kg/h |

| RA500 LOADING STUFFING | |

|---|---|

| POWER SYSTEM | worm screw |

| QUANTITY STUFFING | external continuous |

| DOSAGE REGULATION | single figure |

| MINIMUM LOAD | 10 kg |

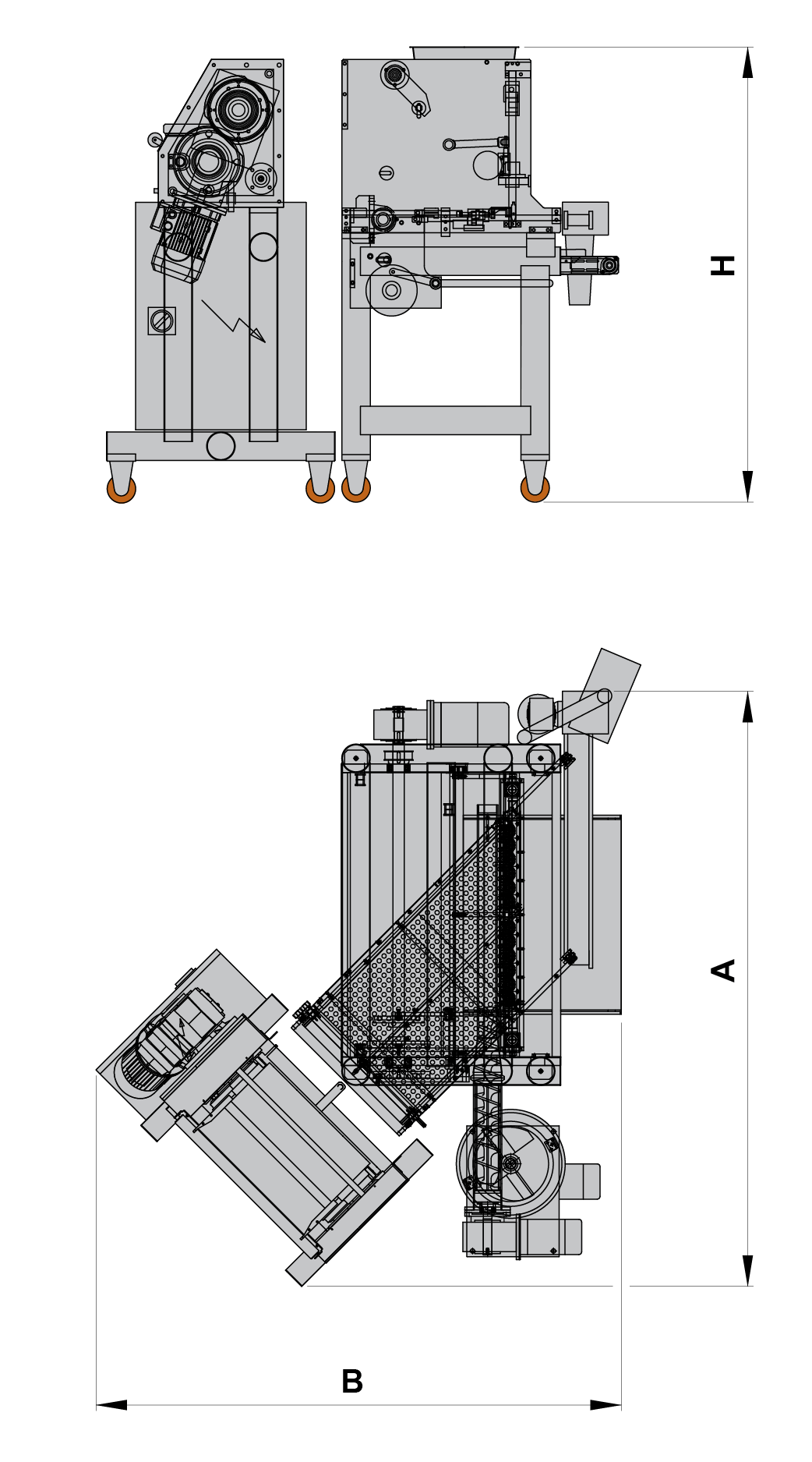

| OVERALL DIMENSIONS | |||||||

|---|---|---|---|---|---|---|---|

| A | 2.620 mm | ||||||

| B | 1.730 mm | ||||||

| H | 1.600 mm | ||||||

| Warning: the values indicated are only approximate and may not, therefore, be considered binding. | |||||||

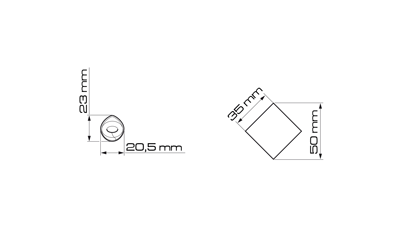

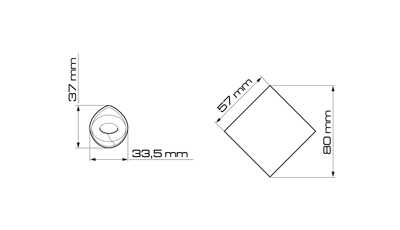

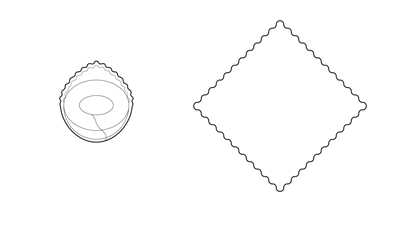

| TB500-13F1 Tortellino format | |

|---|---|

| CUT/IMPRINT DIMENSION | 35 x 35 mm (smooth)* |

| FINISHED TORTELLINO WEIGHT | da 1,8 a 2,2 gr. |

| IMPRESSION OF NUMBER | 13 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 13 |

| RATE PRODUCTION | up to 150 kg/h |

| *A request can be ragged | |

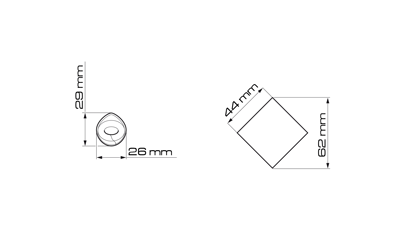

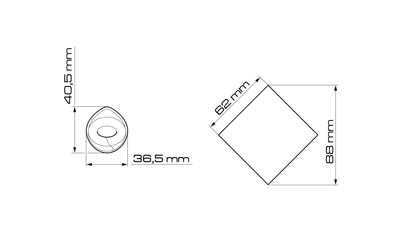

| TC500-10F1 Tortellino format | |

|---|---|

| CUT/IMPRINT DIMENSION | 44 x 44 mm (smooth)* |

| FINISHED TORTELLINO WEIGHT | 3,5 to 4,0 gr. |

| IMPRESSION OF NUMBER | 10 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 10 |

| RATE PRODUCTION | up to 220 kg/h |

| *A request can be ragged | |

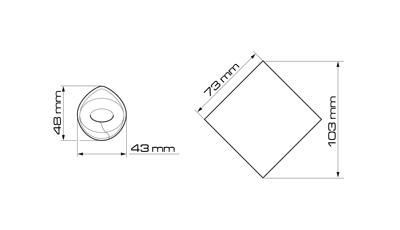

| TE500-8F1 Cappelletto format | |

|---|---|

| CUT/IMPRINT DIMENSION | 57 x 57 mm (smooth)* |

| FINISHED CAPPELLETTO WEIGHT | 6,8 to 7,2 gr. |

| IMPRESSION OF NUMBER | 8 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 8 |

| RATE PRODUCTION | up to 280 kg/h |

| *A request can be ragged | |

| TF500-7F1 Tortellone format | |

|---|---|

| CUT/IMPRINT DIMENSION | 62 x 62 mm (smooth)* |

| FINISHED TORTELLONE WEIGHT | da 8 a 9 gr. |

| IMPRESSION OF NUMBER | 7 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 7 |

| RATE PRODUCTION | up to 320 kg/h |

| *A request can be ragged | |

| TT500-6F1 Tortellone format | |

|---|---|

| CUT/IMPRINT DIMENSION | 73 x 73 mm (smooth)* |

| FINISHED TORTELLONE WEIGHT | da 14 a 15 gr. |

| IMPRESSION OF NUMBER | 6 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 6 |

| RATE PRODUCTION | up to 380 kg/h |

| *A request can be ragged | |

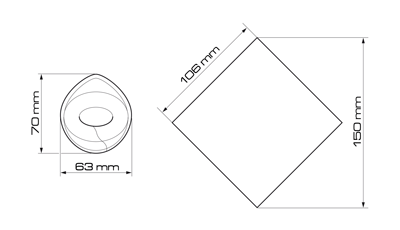

| TO500-4F1 Cappellaccio format | |

|---|---|

| CUT/IMPRINT DIMENSION | 106 x 106 mm (smooth)* |

| FINISHED CAPPELLAC. WEIGHT | 28 to 30 gr. |

| IMPRESSION OF NUMBER | 4 diagonal (Patented) |

| BEAT FOR REPLAC. PRODUCTS | 4 |

| RATE PRODUCTION | up to 420 kg/ora |

| *A request can be ragged | |

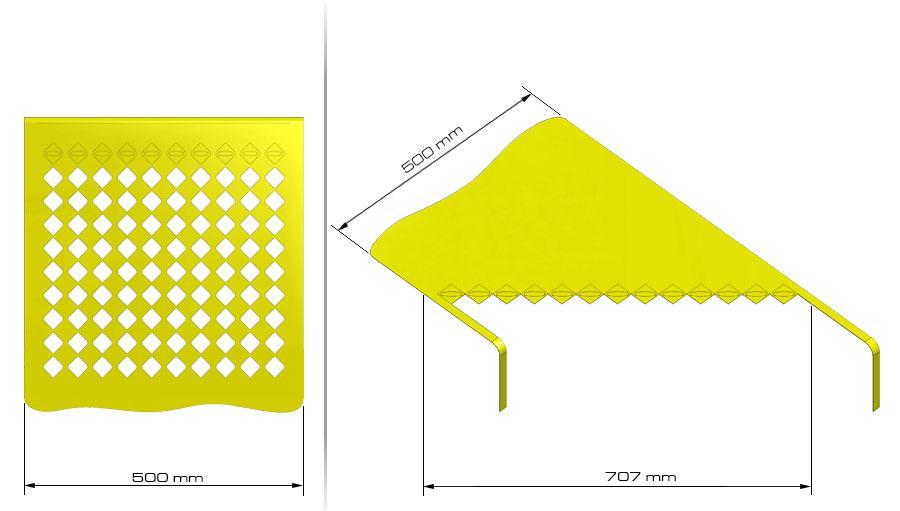

Example of ragged sheet

NP 500 Forming machine OPERATING CYCLE (Loading left)

The OPERATING CYCLE is designed to ensure maximum use of the pasta sheet. Use any type of fresh filling to ensure a high-quality, finished product encapsulating in full all the traditions of stuffed pasta shapes from Emilia.

Pasta dough made using pasta makers or presses, produced by us or other manufacturers, is transferred from either a special reel, or directly from the pasta sheet maker connected upstream, and rolled to the thickness required by the rolling unit using a pair of large-diameter rollers.

The rollers operate at varying speeds to ensure the tension of the pasta sheet is correct and just the right amount of dough is supplied to the forming unit.

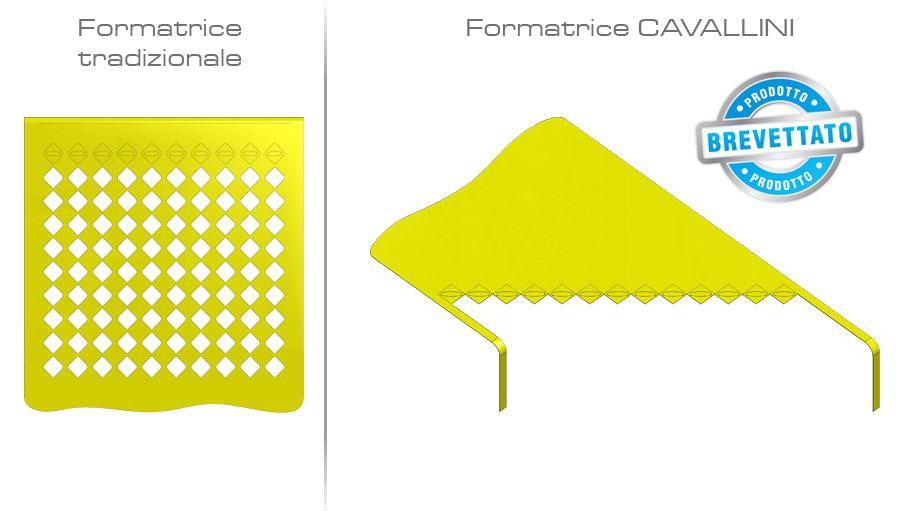

The pasta is transferred to a horizontal conveyor (patented) which positions the pasta diagonally relative to the cutter.

The pump or screw feeder loading unit supplies the filling injection system.

The latter uses a dosing chamber to supply the pre-forming bars with just the right amount of filling for the pasta shape being produced.

The pasta and the dosed filling are transferred from the pre-forming bars downwards towards the forming area.

As it is transferred the pasta is folded into a triangle and then wrapped around a fixed forming stop by rotary folders.

The resulting tortellini or tortelloni are unloaded into baskets and transferred automatically to the downstream processing and packaging units.

The machine is electro-mechanical.

The operating units are mounted on sturdy wheels to facilitate positioning in a flexible production system.

The electronic and electrical control units, in compliance with the modularity of the machine, are housed in electrical cabinets connected directly with the individual modules and the mains power supply.

The operator control panel and interface is used to monitor all the machine functions.

It is also used for troubleshooting.

Pasta dough made using pasta makers or presses, produced by us or other manufacturers, is transferred from either a special reel, or directly from the pasta sheet maker connected upstream, and rolled to the thickness required by the rolling unit using a pair of large-diameter rollers.

The rollers operate at varying speeds to ensure the tension of the pasta sheet is correct and just the right amount of dough is supplied to the forming unit.

The pasta is transferred to a horizontal conveyor (patented) which positions the pasta diagonally relative to the cutter.

The pump or screw feeder loading unit supplies the filling injection system.

The latter uses a dosing chamber to supply the pre-forming bars with just the right amount of filling for the pasta shape being produced.

The pasta and the dosed filling are transferred from the pre-forming bars downwards towards the forming area.

As it is transferred the pasta is folded into a triangle and then wrapped around a fixed forming stop by rotary folders.

The resulting tortellini or tortelloni are unloaded into baskets and transferred automatically to the downstream processing and packaging units.

The machine is electro-mechanical.

The operating units are mounted on sturdy wheels to facilitate positioning in a flexible production system.

The electronic and electrical control units, in compliance with the modularity of the machine, are housed in electrical cabinets connected directly with the individual modules and the mains power supply.

The operator control panel and interface is used to monitor all the machine functions.

It is also used for troubleshooting.

The innovative design solution, whereby the pasta sheet is processed at 45° relative to the forming line, enables more of the dough to be processed and therefore ensures more productivity than when pasta sheets of the same size are processed on other types of machines.